A turnkey decarbonization solution installed on your industrial site, which enhances your territory

YOUR FACTORIES ARE GOING TO HELP

THE ECOLOGICAL TRANSITION

This map is interactive, click to find out more

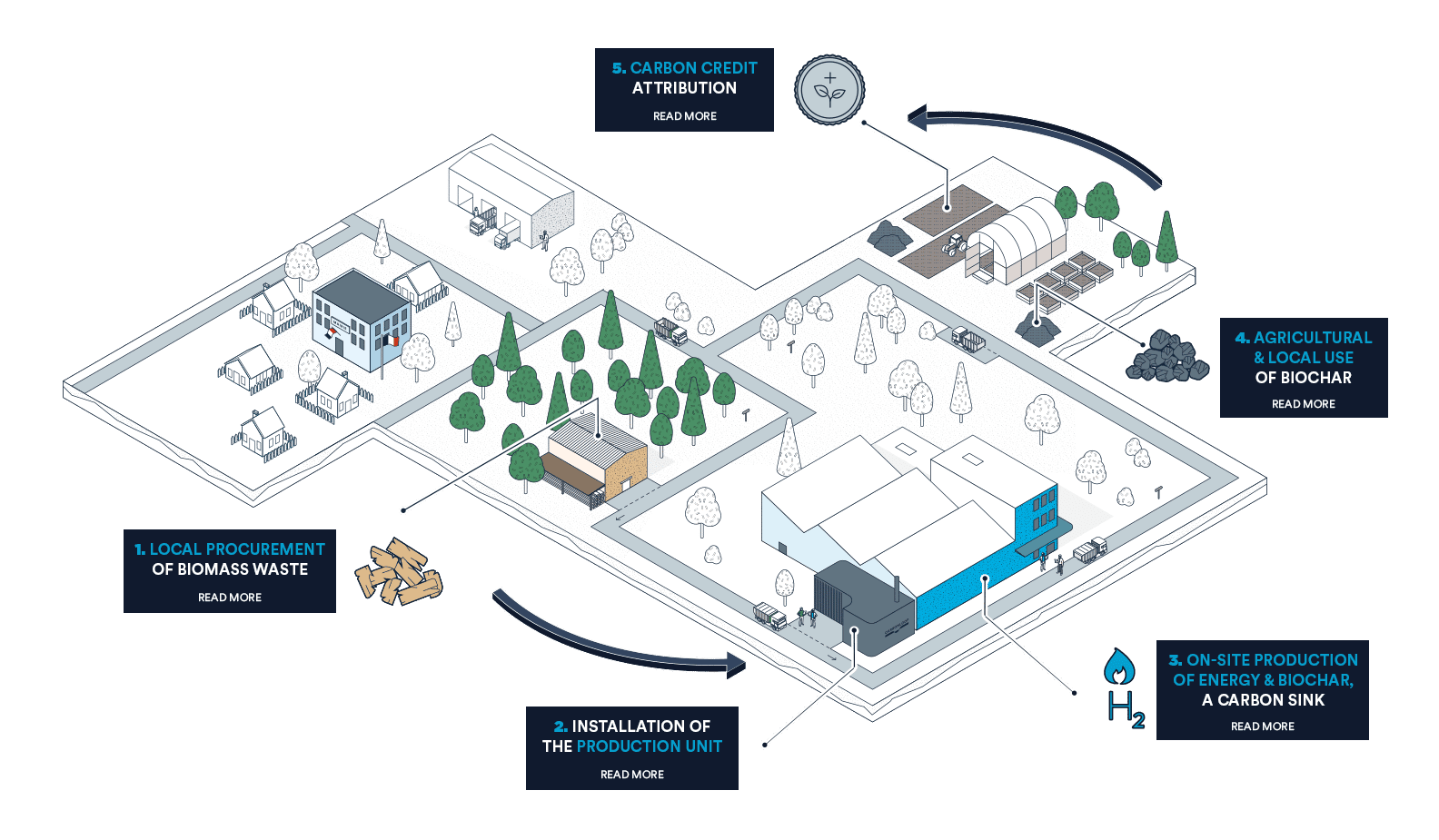

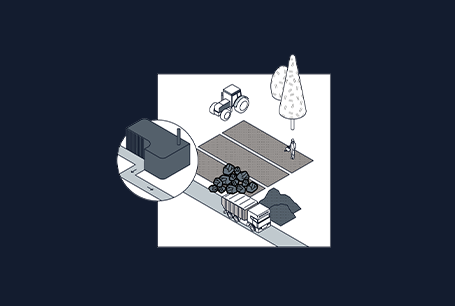

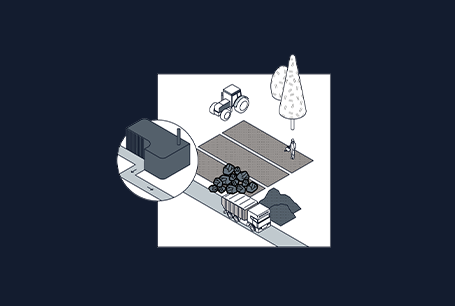

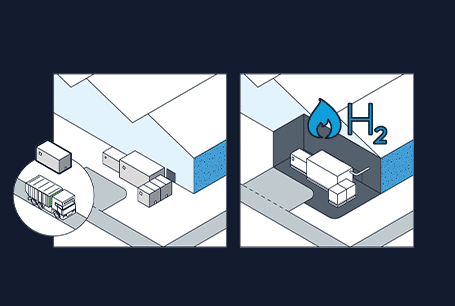

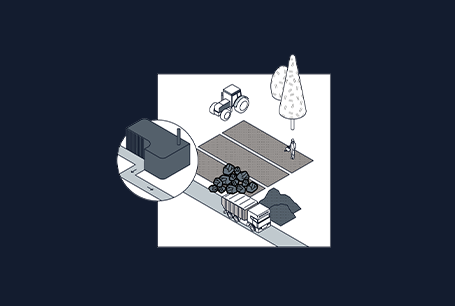

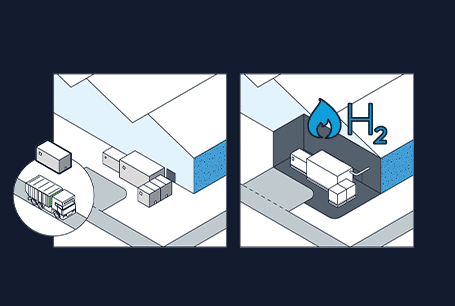

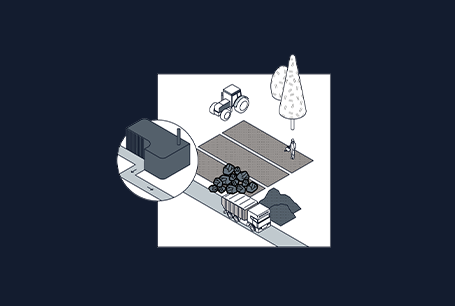

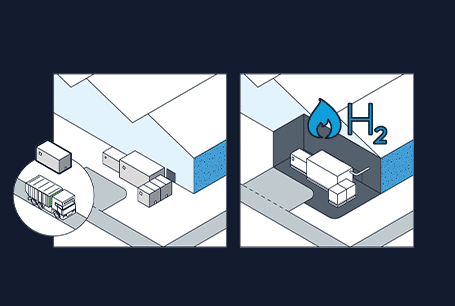

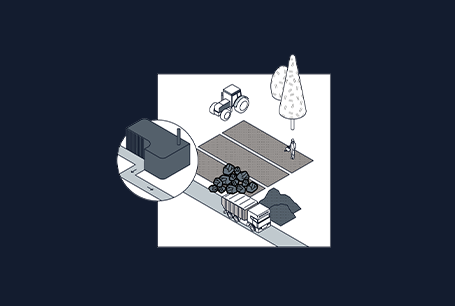

- 1. LOCAL PROCUREMENT OF BIOMASS WASTE

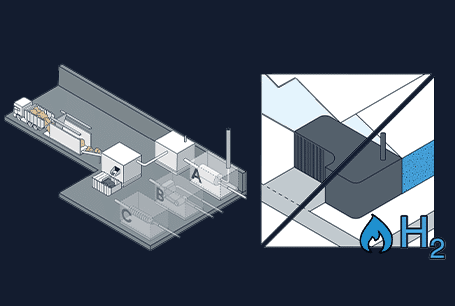

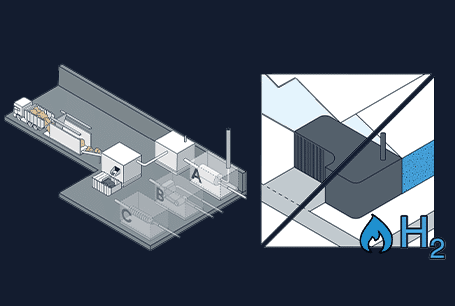

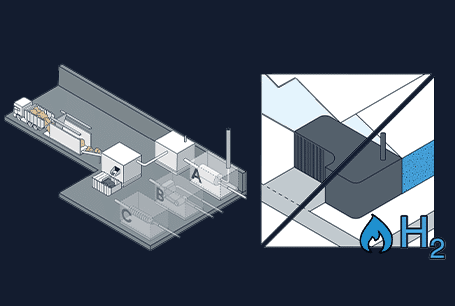

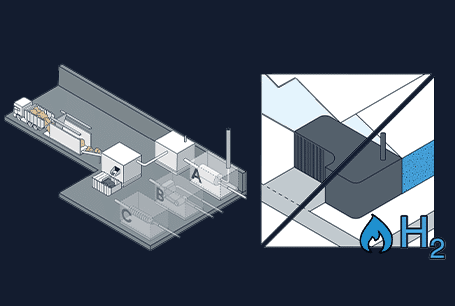

- 2. INSTALLATION OF THE PRODUCTION UNIT

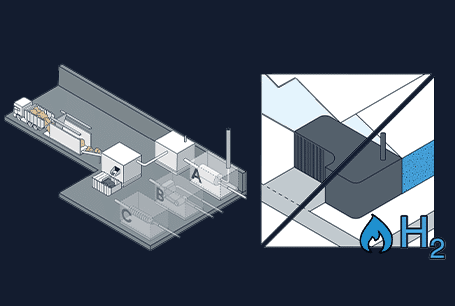

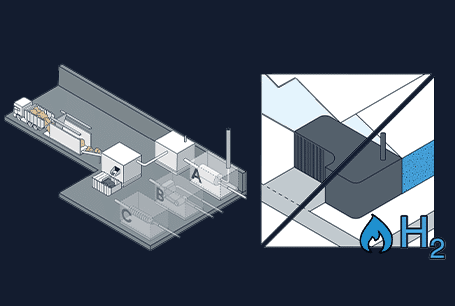

- 3. ON-SITE PRODUCTION OF ENERGY & BIOCHAR, A CARNON SINK

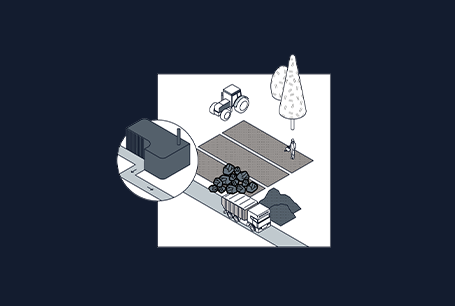

- 4. AGRICULTURAL & LOCAL USE OF BIOCHAR

- 5. CARBON CREDIT ATTRIBUTION

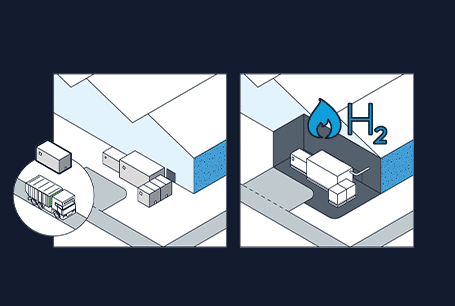

The Carbonloop production unit is supplied locally with biomass residues that would not

otherwise be used (natural or industrial residues from forest maintenance, agriculture

or the wood industry, such as bark, wood chips or straw).

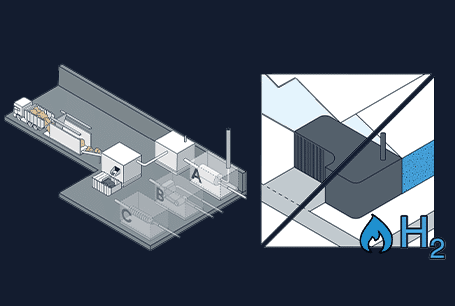

The production unit consists of 3 modules, each the size of a 40-foot container,

which arrive already assembled. It is easy to install on an industrial site.

The modules produce renewable energy from biomass using pyrolysis.

When heated in a low-oxygen atmosphere to around 500°C, the biomass produces a solid residue, biochar, and a synthesis gas.

The resulting solid part, biochar, sequesters carbon from the biomass for several hundred years.

This plant-based charcoal is therefore a powerful carbon sink, and as such is listed as a "Negative Emission Technology"

by the IPCC.

Biochar can be put to many uses : building material, water filtration, soil enrichment.

It improves the potential of natural fertilisers and therefore crop yields,

while reducing fertiliser inputs.

The carbon sequestration in the biochar is certified by very high-quality carbon credits.

Carbonloop ensures this certification with international labels and transfers these carbon credits to the company,

which can then integrate them into its carbon accounting. This enables the company to offset

its carbon emissions directly on site and not on the other side of the world.

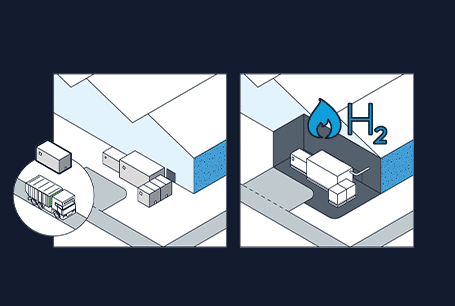

- 1. LOCAL PROCUREMENT OF BIOMASS WASTE

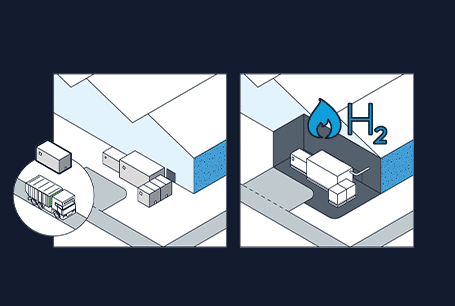

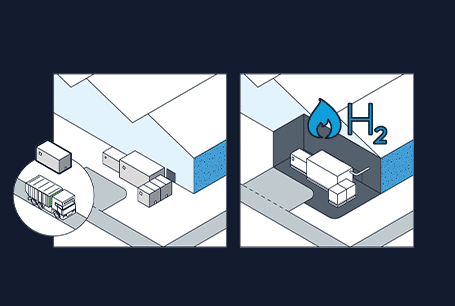

- 2. INSTALLATION OF THE PRODUCTION UNIT

- 3. ON-SITE PRODUCTION OF ENERGY & BIOCHAR, A CARNON SINK

- 4. AGRICULTURAL & LOCAL USE OF BIOCHAR

- 5. CARBON CREDIT ATTRIBUTION

The Carbonloop production unit is supplied locally with biomass residues that would not

otherwise be used (natural or industrial residues from forest maintenance, agriculture

or the wood industry, such as bark, wood chips or straw).

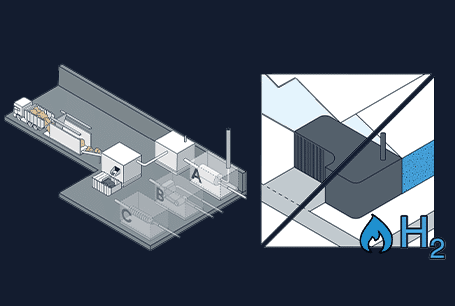

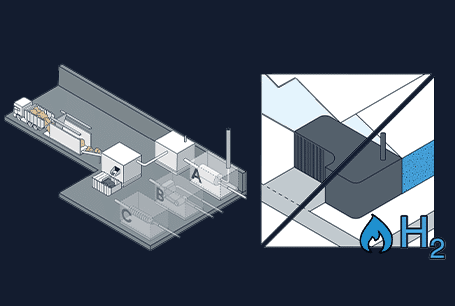

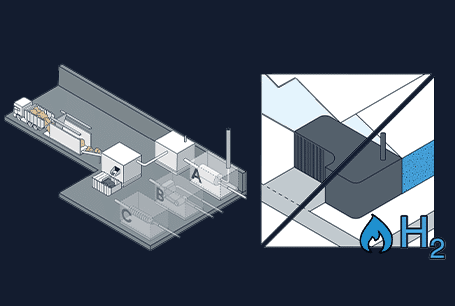

The production unit consists of 3 modules, each the size of a 40-foot container,

which arrive already assembled. It is easy to install on an industrial site.

The modules produce renewable energy from biomass using pyrolysis.

When heated in a low-oxygen atmosphere to around 500°C, the biomass produces a solid residue, biochar, and a synthesis gas.

The resulting solid part, biochar, sequesters carbon from the biomass for several hundred years.

This plant-based charcoal is therefore a powerful carbon sink, and as such is listed as a "Negative Emission Technology"

by the IPCC.

Biochar can be put to many uses : building material, water filtration, soil enrichment.

It improves the potential of natural fertilisers and therefore crop yields,

while reducing fertiliser inputs.

The carbon sequestration in the biochar is certified by very high-quality carbon credits.

Carbonloop ensures this certification with international labels and transfers these carbon credits to the company,

which can then integrate them into its carbon accounting. This enables the company to offset

its carbon emissions directly on site and not on the other side of the world.

- 1. LOCAL PROCUREMENT OF BIOMASS WASTE

- 2. INSTALLATION OF THE PRODUCTION UNIT

- 3. ON-SITE PRODUCTION OF ENERGY & BIOCHAR, A CARNON SINK

- 4. AGRICULTURAL & LOCAL USE OF BIOCHAR

- 5. CARBON CREDIT ATTRIBUTION

The Carbonloop production unit is supplied locally with biomass residues that would not

otherwise be used (natural or industrial residues from forest maintenance, agriculture

or the wood industry, such as bark, wood chips or straw).

The production unit consists of 3 modules, each the size of a 40-foot container,

which arrive already assembled. It is easy to install on an industrial site.

The modules produce renewable energy from biomass using pyrolysis.

When heated in a low-oxygen atmosphere to around 500°C, the biomass produces a solid residue, biochar, and a synthesis gas.

The resulting solid part, biochar, sequesters carbon from the biomass for several hundred years.

This plant-based charcoal is therefore a powerful carbon sink, and as such is listed as a "Negative Emission Technology"

by the IPCC.

Biochar can be put to many uses : building material, water filtration, soil enrichment.

It improves the potential of natural fertilisers and therefore crop yields,

while reducing fertiliser inputs.

The carbon sequestration in the biochar is certified by very high-quality carbon credits.

Carbonloop ensures this certification with international labels and transfers these carbon credits to the company,

which can then integrate them into its carbon accounting. This enables the company to offset

its carbon emissions directly on site and not on the other side of the world.

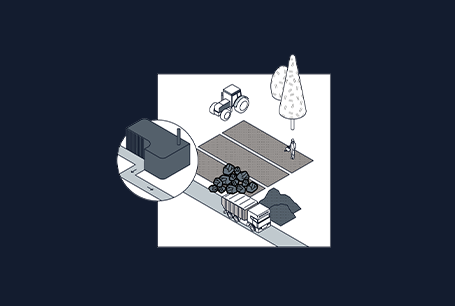

- 1. LOCAL PROCUREMENT OF BIOMASS WASTE

- 2. INSTALLATION OF THE PRODUCTION UNIT

- 3. ON-SITE PRODUCTION OF ENERGY & BIOCHAR, A CARNON SINK

- 4. AGRICULTURAL & LOCAL USE OF BIOCHAR

- 5. CARBON CREDIT ATTRIBUTION

The Carbonloop production unit is supplied locally with biomass residues that would not

otherwise be used (natural or industrial residues from forest maintenance, agriculture

or the wood industry, such as bark, wood chips or straw).

The production unit consists of 3 modules, each the size of a 40-foot container,

which arrive already assembled. It is easy to install on an industrial site.

The modules produce renewable energy from biomass using pyrolysis.

When heated in a low-oxygen atmosphere to around 500°C, the biomass produces a solid residue, biochar, and a synthesis gas.

The resulting solid part, biochar, sequesters carbon from the biomass for several hundred years.

This plant-based charcoal is therefore a powerful carbon sink, and as such is listed as a "Negative Emission Technology"

by the IPCC.

Biochar can be put to many uses : building material, water filtration, soil enrichment.

It improves the potential of natural fertilisers and therefore crop yields,

while reducing fertiliser inputs.

The carbon sequestration in the biochar is certified by very high-quality carbon credits.

Carbonloop ensures this certification with international labels and transfers these carbon credits to the company,

which can then integrate them into its carbon accounting. This enables the company to offset

its carbon emissions directly on site and not on the other side of the world.

- 1. LOCAL PROCUREMENT OF BIOMASS WASTE

- 2. INSTALLATION OF THE PRODUCTION UNIT

- 3. ON-SITE PRODUCTION OF ENERGY & BIOCHAR, A CARNON SINK

- 4. AGRICULTURAL & LOCAL USE OF BIOCHAR

- 5. CARBON CREDIT ATTRIBUTION

The Carbonloop production unit is supplied locally with biomass residues that would not

otherwise be used (natural or industrial residues from forest maintenance, agriculture

or the wood industry, such as bark, wood chips or straw).

The production unit consists of 3 modules, each the size of a 40-foot container,

which arrive already assembled. It is easy to install on an industrial site.

The modules produce renewable energy from biomass using pyrolysis.

When heated in a low-oxygen atmosphere to around 500°C, the biomass produces a solid residue, biochar, and a synthesis gas.

The resulting solid part, biochar, sequesters carbon from the biomass for several hundred years.

This plant-based charcoal is therefore a powerful carbon sink, and as such is listed as a "Negative Emission Technology"

by the IPCC.

Biochar can be put to many uses : building material, water filtration, soil enrichment.

It improves the potential of natural fertilisers and therefore crop yields,

while reducing fertiliser inputs.

The carbon sequestration in the biochar is certified by very high-quality carbon credits.

Carbonloop ensures this certification with international labels and transfers these carbon credits to the company,

which can then integrate them into its carbon accounting. This enables the company to offset

its carbon emissions directly on site and not on the other side of the world.

- 1. LOCAL PROCUREMENT OF BIOMASS WASTE

- 2. INSTALLATION OF THE PRODUCTION UNIT

- 3. ON-SITE PRODUCTION OF ENERGY & BIOCHAR, A CARNON SINK

- 4. AGRICULTURAL & LOCAL USE OF BIOCHAR

- 5. CARBON CREDIT ATTRIBUTION

The Carbonloop production unit is supplied locally with biomass residues that would not

otherwise be used (natural or industrial residues from forest maintenance, agriculture

or the wood industry, such as bark, wood chips or straw).

The production unit consists of 3 modules, each the size of a 40-foot container,

which arrive already assembled. It is easy to install on an industrial site.

The modules produce renewable energy from biomass using pyrolysis.

When heated in a low-oxygen atmosphere to around 500°C, the biomass produces a solid residue, biochar, and a synthesis gas.

The resulting solid part, biochar, sequesters carbon from the biomass for several hundred years.

This plant-based charcoal is therefore a powerful carbon sink, and as such is listed as a "Negative Emission Technology"

by the IPCC.

Biochar can be put to many uses : building material, water filtration, soil enrichment.

It improves the potential of natural fertilisers and therefore crop yields,

while reducing fertiliser inputs.

The carbon sequestration in the biochar is certified by very high-quality carbon credits.

Carbonloop ensures this certification with international labels and transfers these carbon credits to the company,

which can then integrate them into its carbon accounting. This enables the company to offset

its carbon emissions directly on site and not on the other side of the world.

- 1. LOCAL PROCUREMENT OF BIOMASS WASTE

- 2. INSTALLATION OF THE PRODUCTION UNIT

- 3. ON-SITE PRODUCTION OF ENERGY & BIOCHAR, A CARNON SINK

- 4. AGRICULTURAL & LOCAL USE OF BIOCHAR

- 5. CARBON CREDIT ATTRIBUTION

The Carbonloop production unit is supplied locally with biomass residues that would not

otherwise be used (natural or industrial residues from forest maintenance, agriculture

or the wood industry, such as bark, wood chips or straw).

The production unit consists of 3 modules, each the size of a 40-foot container,

which arrive already assembled. It is easy to install on an industrial site.

The modules produce renewable energy from biomass using pyrolysis.

When heated in a low-oxygen atmosphere to around 500°C, the biomass produces a solid residue, biochar, and a synthesis gas.

The resulting solid part, biochar, sequesters carbon from the biomass for several hundred years.

This plant-based charcoal is therefore a powerful carbon sink, and as such is listed as a "Negative Emission Technology"

by the IPCC.

Biochar can be put to many uses : building material, water filtration, soil enrichment.

It improves the potential of natural fertilisers and therefore crop yields,

while reducing fertiliser inputs.

The carbon sequestration in the biochar is certified by very high-quality carbon credits.

Carbonloop ensures this certification with international labels and transfers these carbon credits to the company,

which can then integrate them into its carbon accounting. This enables the company to offset

its carbon emissions directly on site and not on the other side of the world.

- 1. LOCAL PROCUREMENT OF BIOMASS WASTE

- 2. INSTALLATION OF THE PRODUCTION UNIT

- 3. ON-SITE PRODUCTION OF ENERGY & BIOCHAR, A CARNON SINK

- 4. AGRICULTURAL & LOCAL USE OF BIOCHAR

- 5. CARBON CREDIT ATTRIBUTION

The Carbonloop production unit is supplied locally with biomass residues that would not

otherwise be used (natural or industrial residues from forest maintenance, agriculture

or the wood industry, such as bark, wood chips or straw).

The production unit consists of 3 modules, each the size of a 40-foot container,

which arrive already assembled. It is easy to install on an industrial site.

The modules produce renewable energy from biomass using pyrolysis.

When heated in a low-oxygen atmosphere to around 500°C, the biomass produces a solid residue, biochar, and a synthesis gas.

The resulting solid part, biochar, sequesters carbon from the biomass for several hundred years.

This plant-based charcoal is therefore a powerful carbon sink, and as such is listed as a "Negative Emission Technology"

by the IPCC.

Biochar can be put to many uses : building material, water filtration, soil enrichment.

It improves the potential of natural fertilisers and therefore crop yields,

while reducing fertiliser inputs.

The carbon sequestration in the biochar is certified by very high-quality carbon credits.

Carbonloop ensures this certification with international labels and transfers these carbon credits to the company,

which can then integrate them into its carbon accounting. This enables the company to offset

its carbon emissions directly on site and not on the other side of the world.

- 1. LOCAL PROCUREMENT OF BIOMASS WASTE

- 2. INSTALLATION OF THE PRODUCTION UNIT

- 3. ON-SITE PRODUCTION OF ENERGY & BIOCHAR, A CARNON SINK

- 4. AGRICULTURAL & LOCAL USE OF BIOCHAR

- 5. CARBON CREDIT ATTRIBUTION

The Carbonloop production unit is supplied locally with biomass residues that would not

otherwise be used (natural or industrial residues from forest maintenance, agriculture

or the wood industry, such as bark, wood chips or straw).

The production unit consists of 3 modules, each the size of a 40-foot container,

which arrive already assembled. It is easy to install on an industrial site.

The modules produce renewable energy from biomass using pyrolysis.

When heated in a low-oxygen atmosphere to around 500°C, the biomass produces a solid residue, biochar, and a synthesis gas.

The resulting solid part, biochar, sequesters carbon from the biomass for several hundred years.

This plant-based charcoal is therefore a powerful carbon sink, and as such is listed as a "Negative Emission Technology"

by the IPCC.

Biochar can be put to many uses : building material, water filtration, soil enrichment.

It improves the potential of natural fertilisers and therefore crop yields,

while reducing fertiliser inputs.

The carbon sequestration in the biochar is certified by very high-quality carbon credits.

Carbonloop ensures this certification with international labels and transfers these carbon credits to the company,

which can then integrate them into its carbon accounting. This enables the company to offset

its carbon emissions directly on site and not on the other side of the world.

,

- 1. LOCAL PROCUREMENT OF BIOMASS WASTE

- 2. INSTALLATION OF THE PRODUCTION UNIT

- 3. ON-SITE PRODUCTION OF ENERGY & BIOCHAR, A CARNON SINK

- 4. AGRICULTURAL & LOCAL USE OF BIOCHAR

- 5. CARBON CREDIT ATTRIBUTION

The Carbonloop production unit is supplied locally with biomass residues that would not

otherwise be used (natural or industrial residues from forest maintenance, agriculture

or the wood industry, such as bark, wood chips or straw).

The production unit consists of 3 modules, each the size of a 40-foot container,

which arrive already assembled. It is easy to install on an industrial site.

The modules produce renewable energy from biomass using pyrolysis.

When heated in a low-oxygen atmosphere to around 500°C, the biomass produces a solid residue, biochar, and a synthesis gas.

The resulting solid part, biochar, sequesters carbon from the biomass for several hundred years.

This plant-based charcoal is therefore a powerful carbon sink, and as such is listed as a "Negative Emission Technology"

by the IPCC.

Biochar can be put to many uses : building material, water filtration, soil enrichment.

It improves the potential of natural fertilisers and therefore crop yields,

while reducing fertiliser inputs.

The carbon sequestration in the biochar is certified by very high-quality carbon credits.

Carbonloop ensures this certification with international labels and transfers these carbon credits to the company,

which can then integrate them into its carbon accounting. This enables the company to offset

its carbon emissions directly on site and not on the other side of the world.

CARBON-NEGATIVE ENERGIES

TO MATCH YOUR NEEDS

BECOME A RENEWABLE

GAS CONSUMER

Produced directly on site.

Possibility of supplying renewable

electricity and heat by cogeneration.

BECOME A RENEWABLE

HYDROGEN CONSUMER

Produced directly on site.

Ideal for distribution stations,

freeing them from transport constraints.

TOGETHER, LET’S TURN

ECOLOGICAL CONSTRAINTS INTO

BUSINESS OPPORTUNITIES

We are driven by our ambition to bring about the emergence of a positive

new industrial model that integrates carbon into its strategy and decisions.

WHY CARBONLOOP?

We are convinced that industries, through the energy they consume,

can provide the solution to the climate change challenge whilst ensuring business development,

and having a positive impact on their regions.

OUR SERVICE ENABLES MANUFACTURERS

TO TRANSFORM THEIR MODEL…

FOR THE ON-SITE PRODUCTION OF RENEWABLE ENERGIES

We manage all of the renewable energy production cycle, from the supply of biomass to use and maintenance.

FOR QUALITY

CARBON SEQUESTRATION

Our requirement is that sequestration is long-term, analytically quantifiable and local. It enables you to obtain audited, traced and verifiable carbon credits.

FOR LOCAL IMPACT

WITH REGIONAL EFFECTS

As part of our procurement strategy, we source our biomass within a radius of 100 km maximum. The biochar is then used to on local agricultural land to improve soil health.

CONTACT US

AND LET’S WORK TOGETHER,

TO CREATE THE INDUSTRY

OF TOMORROW

Find out about vacancies at Carbonloop and

become part of the energy powering positive industry.